Naim Factory Tour

Jason Kennedy takes a tour of Naim’s factory

James and I spent a very pleasant afternoon being shown around Naim’s impressive Salisbury factory. The company’s premises have grown organically from the first building it occupied into a series of adjacent properties, at least that’s the way it feels on the inside, you could easily get lost in the place. It’s densely packed despite the fact that it makes everything to order so does not keep stock in the usual sense, there’s no huge stock room like you find in other factories. The despatch area is also the stock room and it was a busy place when we visited.

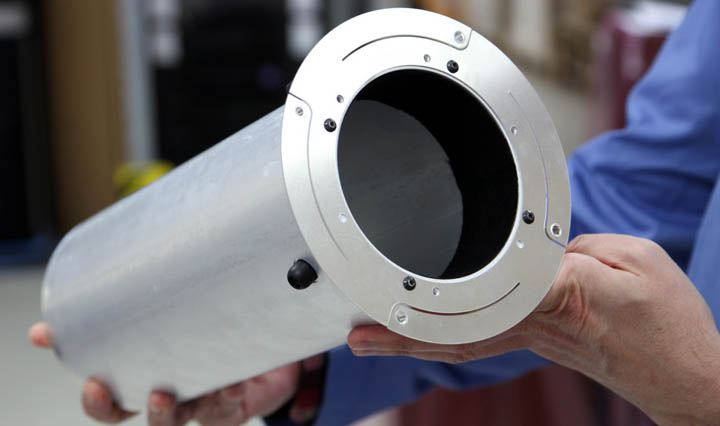

Naim employs nearly 200 people and builds all of its own products (except the mu–so) although it doesn’t make wood and metalwork in–house but it populates circuit boards and does all assembly, testing and QC on the premises. It also services everything that it has ever made in a very busy service and repair department where they log details of every incoming unit and take photos of the most extreme examples. For instance, one customer had made an outboard power supply by putting the transformer in a Tupperware box , another had re–wired a complete product with a different type of cable! Needless to say these are not practises that Naim recommends.

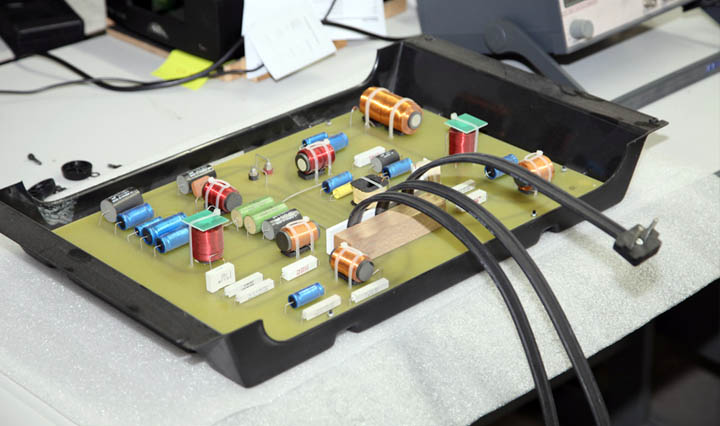

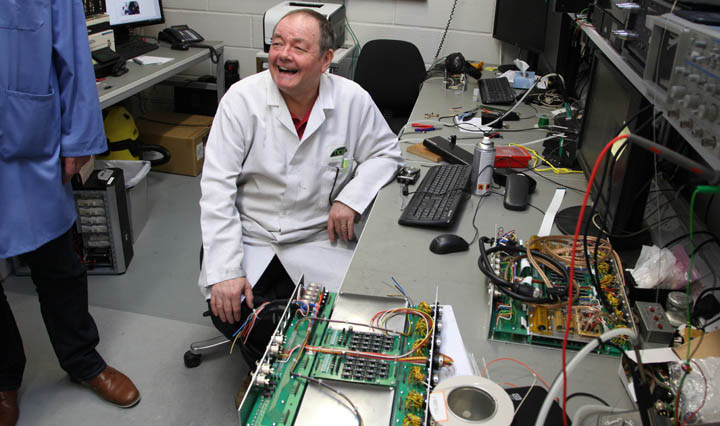

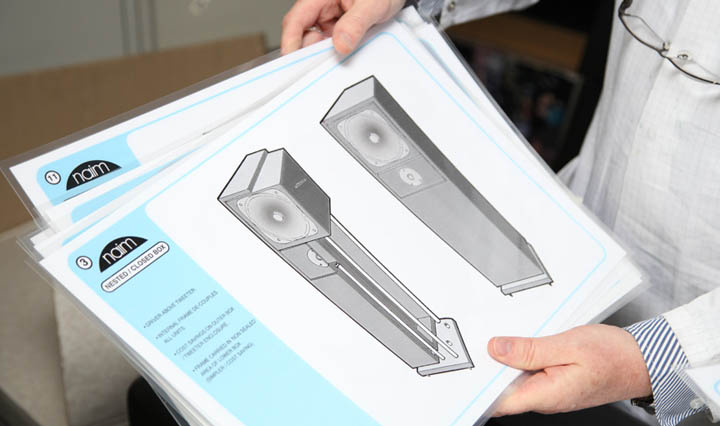

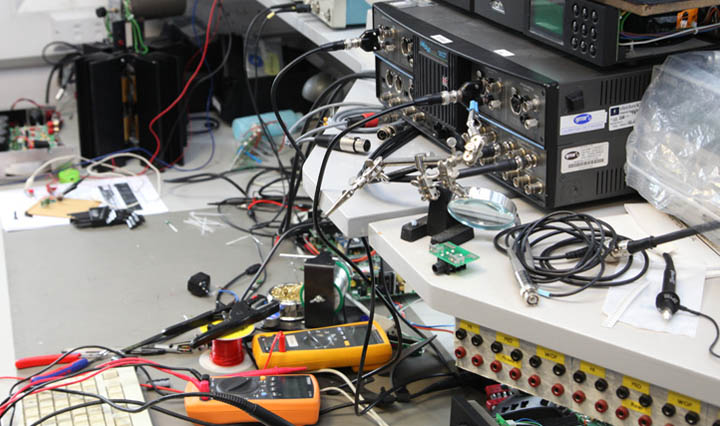

What strikes you about the company is its depth of knowledge about the subject and commitment to quality control in the context of a constant desire to push the capabilities of its products. Its streaming devices now account for 30% of turnover and developing them has resulted in a considerable expansion in the R&D department, which has doubled in the last five years and now numbers around 40 specialist engineers in various disciplines. Some are software experts who spend far too long looking at code while others have a computer on one desk and tools and test rigs on another. There are electronic, mechanical and software engineers in this department and they share the most compact and densely packed listening room I have seen in some time. We found director and head of R&D Roy George in the more lavish surrounds of the listening room used to demonstrate to distributors and dealers, but he says that the smaller room is so familiar that he finds it very easy to work in. On this occasion he was refining passive crossovers for the Ovator S800 which is just too big for the other space. What’s impressive is that Roy manages to get time to listen while running a department of that size. He must be committed to the cause.

Naim is of the opinion that multi–brand systems are a thing of the past when it comes to electronics. Other manufacturers take this one step further and believe that multibox systems are a dying breed, but should it prove true Naim has this angle covered with its Uniti range. In both cases we are talking about market sectors, and those of us in search of high fidelity are rather more flexible. We appreciate the ‘electronic lego’ that Naim produces and which makes upgrading so much easier than other routes.

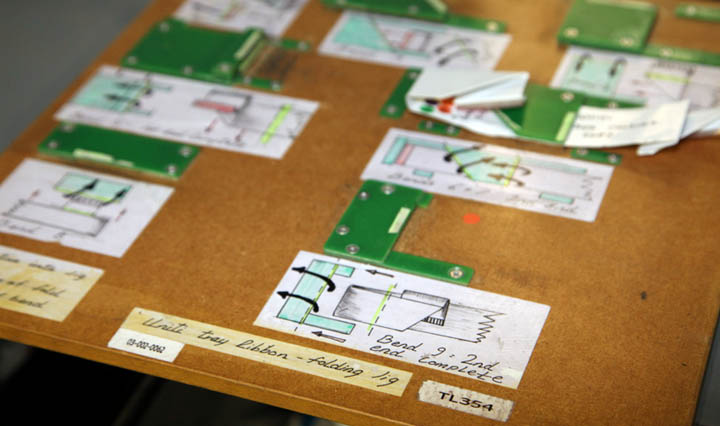

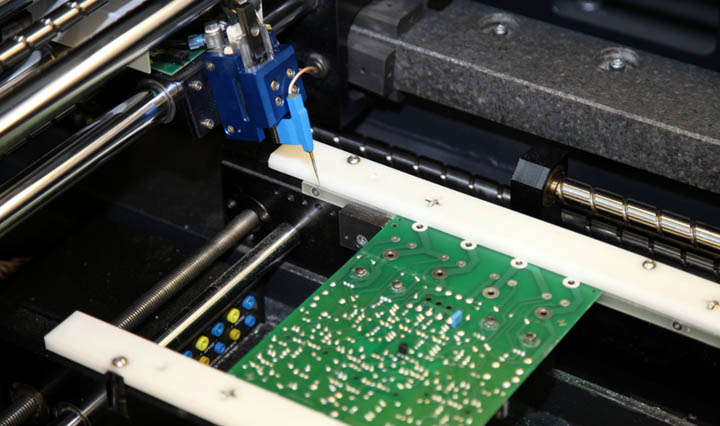

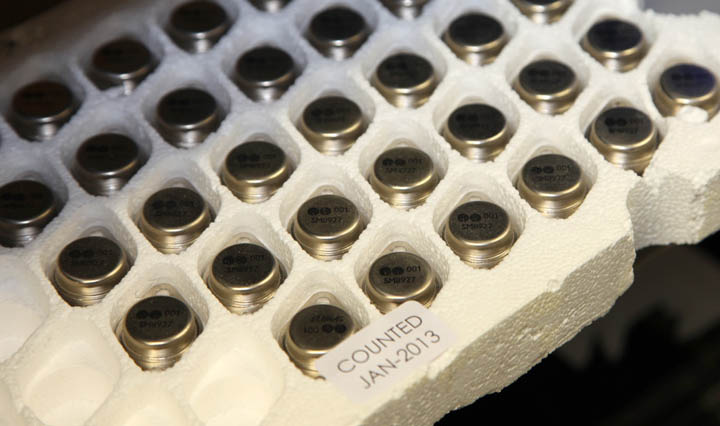

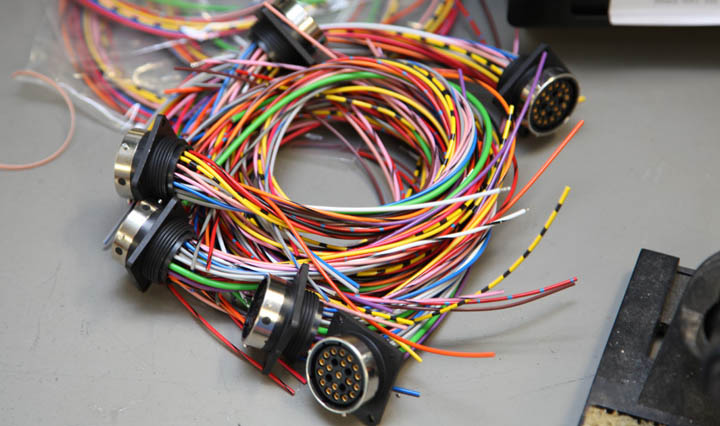

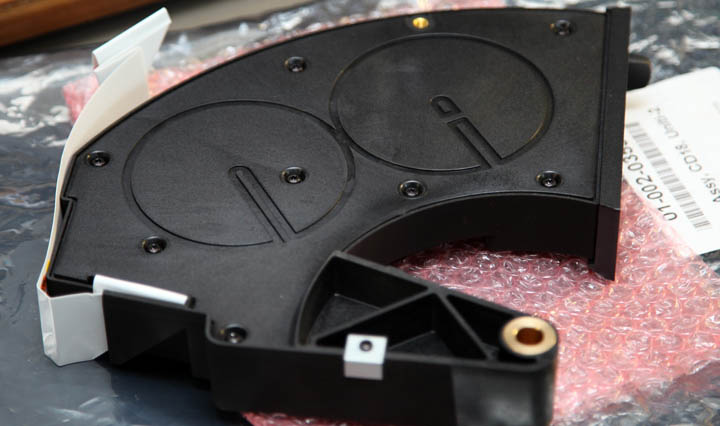

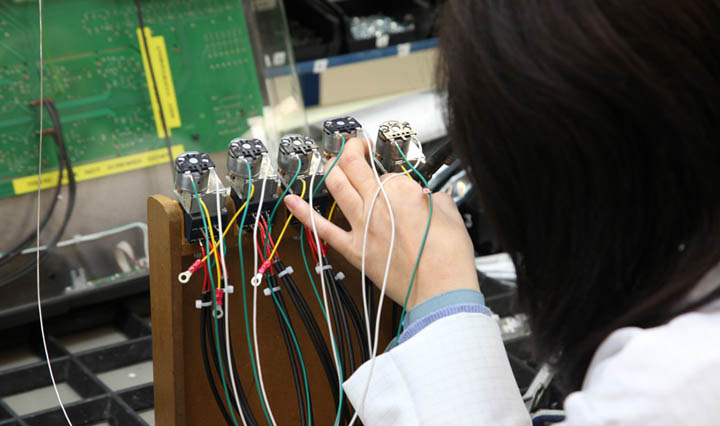

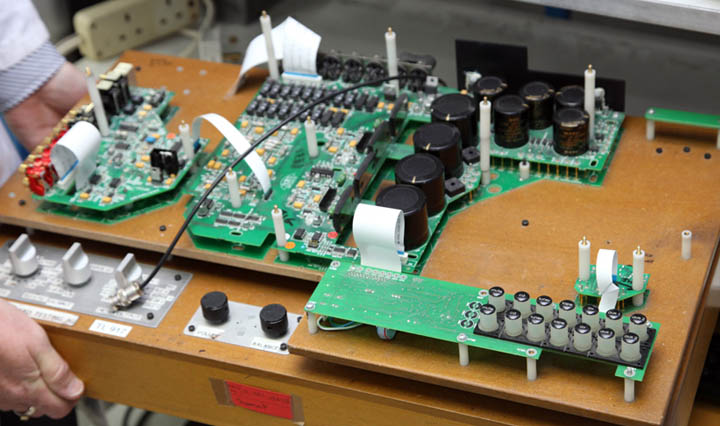

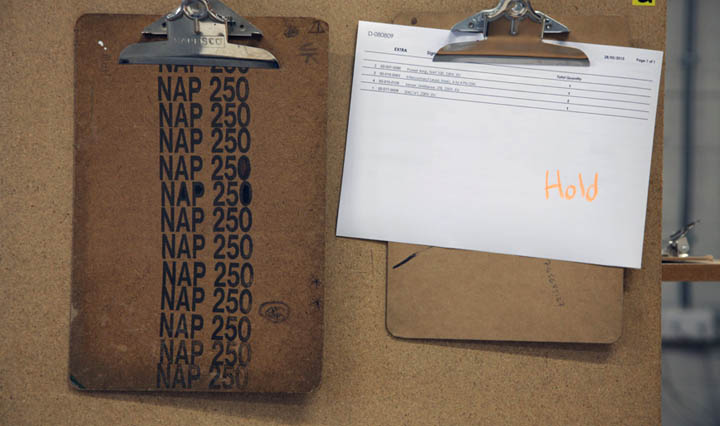

The six week build time of a Naim component starts in the goods–in department where parts are inspected and measured to ensure that they are up to spec. They have quite a few boxes of toroidal mains transformers in here which are being returned because it’s getting harder to source examples that meet their high specifications, and there are also quite a few pieces of metalwork that either have minute cosmetic problems or are not machined precisely enough for Naim’s and ultimately our requirements. Electronic parts like capacitors and transistors are measured and pair matched using a number of test rigs that were built in–house because their requirements are so particular. Once parts are selected they are placed on circuit boards and soldered by hand or with a huge flow soldering machine that we were told – and it’s easy to believe – took a lot of effort to get up to its first floor location.

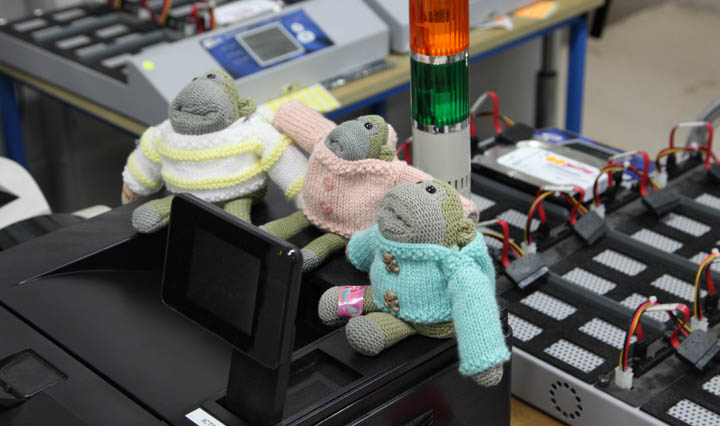

Boards and chassis are then put together along with all the other elements in the production area on the ground floor, an area where the QC department has almost as many staff as production. This is also where units are soak tested to ensure that they will operate reliably in customers’ homes. Casework is not closed up until it gets to the packing and despatch area.

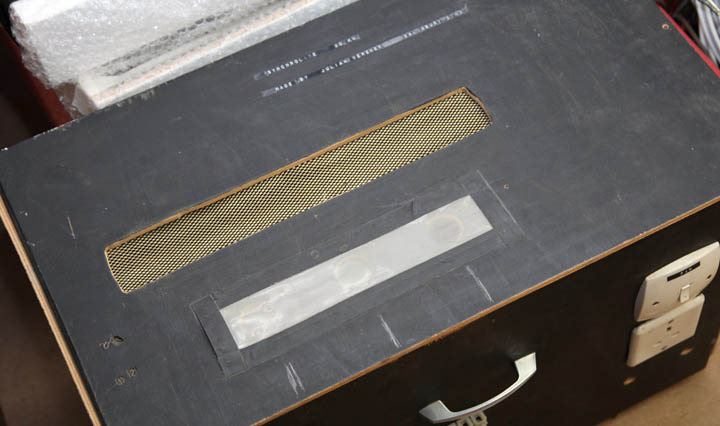

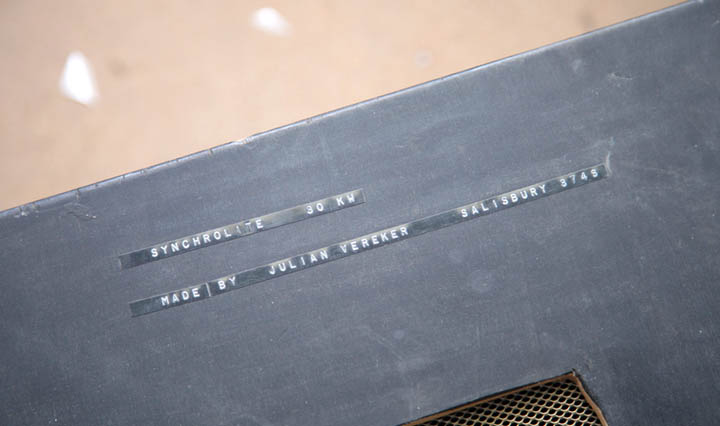

Up in the attic above despatch was the treasure trove that James dreams about: dusty shelves full of vintage components often of non standard variety. For instance there was a time when it was more economical to build in New Zealand than to ship there and we found a NAC 225 made by the Avalon Radio Corp in Auckland. Rather less auspicious is a plywood box with switches and vents on it that has a label on indicating that it’s a Synchrolite device made by Julian Vereker in the very early days. I think we could have left James up there all day but time was pressing and we took advantage of Naim’s free canteen for lunch. This is in a sizeable room that was apparently once the dem room; somebody must have worked out that worker satisfaction was served by food as well as great sound. Mind you, they do have the best factory radio I’ve yet encountered.

Despite the number of people working there, Naim’s facility has a more intimate feel about it than other companies of a similar size. This is partly a result of the organic way in which the facility has expanded and partly that it values results over image. You don’t get the impression that it spends too much money on looks but concentrates on developing and building products that deliver results which please both us and them. The people there obviously care about sound. You would think that this was the case with all manufacturers in this business but it’s not always so, the bottom line often gets in the way as does the desire for status among the people in control. The music–nuts–to–business–people ratio leans in the right direction at Naim and that’s what sets the company apart.

The other quality that is very rare is the combination of traditional values and experience with new technology. Naim can service an amplifier from the seventies and creates streaming software to run bang up to the moment streaming systems. The majority of tech savvy companies are not bothered about the past; five years is the life expectancy of many products with some kind of operating system onboard and one suspects that this area will prove the biggest challenge for Naim in the future. But their approach has always been to keep their products going, the WEEE directive is irrelevant with these products as the value of vintage HiCaps reveals. A Naim, as one of the posters undoubtedly decries, is not just for Christmas.

‘Purveyors of iconic British Hi-Fi’ | tel: 01727 810047 | email: tunes@tomtomaudio.co.uk

All images © 2020 Tom Tom Audio